High capacity laboratory glassware washer and dryer LAB 1500

The laboratory washer LAB 1500 is a high capacity glassware washer and dryer specially developed for laboratories that require to clean large quantities of items on a daily basis. This lab washer features a full visibility motorized space-saving sliding down door.

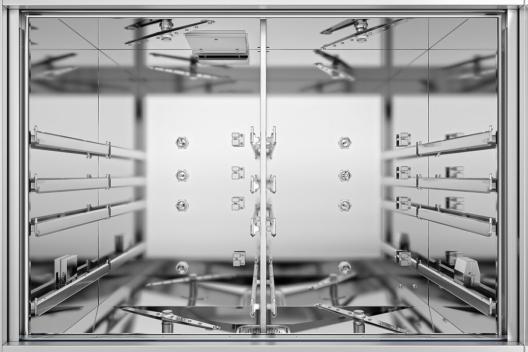

This unit is capable of injection washing on up to 6 levels with 8 possible rack locations, providing maximum flexibility through multiple chamber configurations, depending on the height of the loaded items.

Two heavy duty washing pumps dedicated to separate washing – providing a high water flow rate combined with adequate spray pressure – ensure glassware outstanding washing results. The availability of an optional pre heated tank allows to perform a final non recirculated rinse.

LAB1500 laboratory washer is capable of injection washing on up to 6 levels with 8 possible rack locations, providing maximum flexibility through multiple chamber configurations, depending on the height of the loaded items. All the levels are equipped with telescopic bearing rails that enable easy and safe loading and unloading of the glassware. The upper levels can be removed depending on the height of the loaded glassware.

As standard, two peristaltic pumps providing precise dosing of liquid chemical agents. A convenient hinged door allowing for easy access to storage of chemical tanks of up to two 10 liters. The optional filtered forced air drying system with adjustable time and temperature settings help to ensure the complete inside and outside drying of all the glassware. To assure full control of the process, the device is controlled by a PLC digital controller with a user-friendly color touch screen HMI.

Key features of LAB1500 washer

Flexible solutions

The electrical or steam stainless steel heat exchanger provides rapid heating of water in washer sump.

Drying efficacy

Built-in HEPA 14 filtered forced air drying system with adjustable temperature and time settings help to ensure the complete internal and external drying of all the glassware.

Tank for no-recirculated final rinse

A pre-heating tank configured with electrical heating elements allows for a no-recirculate final rinse.

Process quality

Flow meters for redundancy chemical dosing control and a conductivity sensor for accurate measuring of the conductivity value during the final rinse are available as options.

7" user-friendly HMI

Industrial PLC with intuitive 7″ touch-screen HMI, allowing for 65 programming options.

Full traceability

On board integrated thermal printer for recording washing phases with detailed information. USB port for the back-up and restore of the software. Audit Trail / User Management / Electronic Signature according 21 CFR 11 available upon request.

High and flexible capacity

With a washing chamber volume of - 484 liters the LAB 1500 has the largest chamber capacity in the market within the smallest footprint. The device is capable of injection washing on up to 6 levels with 8 possible rack locations, providing maximum flexibility through multiple chamber configurations.

Washing efficacy

High-quality AISI 316 L washing chamber and four rotatory spray arms, two on the bottom and two on the top of the chamber ensure optimal washing performance. Additional spray arms are available on dedicated upper level wash carts.

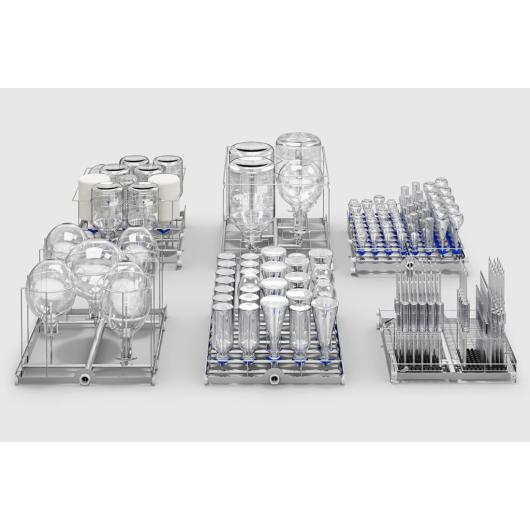

Wide range of racks, inserts, trays and accessories

A comprehensive choice of racks and accessories to meet different capacity and cleaning demands, allowing to maximize the numbers of different utensils and glassware that can be washed, preventing movement and damage, and ensuring complete coverage of the loads.

Aquatic animals tank package

Specific kit designed for the reprocessing of the aquatic tank used in vivarium and research facilities. It includes three chemical dosage pumps, an upgrade to washing circuit, flow meters, and conductivity probe.

Complete traceability

SteelcoData View software is designed to monitor, collect and record data and cycles parameters (time, temperature, cycle consumption, historical alarm data) from up to 15 Steelco devices to one computer. Information collected in real-time is traced and efficiently visualized for device monitoring and data management.