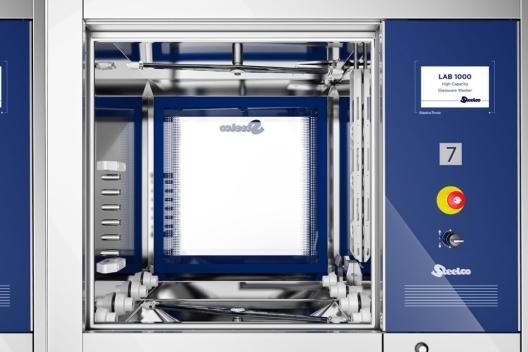

High capacity pass-through double door glassware washer LAB 1000

LAB 1000 is a large capacity glassware washer specially developed for laboratories that require to clean large quantities of items on a daily basis. This fully automatic frontal loading glassware washer with motorized vertical sliding down door is available in both single or double door pass through version. This latter version includes a door interlock system to prevent both doors being opened simultaneously, thereby eliminating cross contamination between two classified areas.

Steelco LAB 1000 ensures outstanding washing and drying results of all laboratory glassware thanks to the accurate distribution of the air on all the chamber zones and on the washing cart levels. A built-in pre-heating tank is available as option to perform faster washing cycles. In this configuration the washer can perform a complete cycle in less than 40 minutes. The HEPA 14 filtered forced air drying system helps achieve complete drying of your glassware’s exterior and interior.

The washing cart system is developed starting from a base injection washing cart that can fit up to 4 removable injection cassettes on 2 levels. The upper levels can be removed depending on the height of the loaded glassware. Loading and unloading washing carts operations can be done at an ergonomic height by using manual or automatic single loading/unloading transfer trolleys.

High and flexible capacity

Washing and drying system on up to 3 independent levels. The unit is able to treat carboys and large glassware up to a height of 605 mm / 23.62″.

Process quality

Flow meter for accurate volumetric dosing of chemicals and a conductivity sensor for measuring of the conductivity value during the final rinse phase are available upon request.

Drying efficacy

Built-In HEPA 14 filtered forced air drying system ensuring the complete internal and external drying of all the glassware. Adjustable time and temperature settings for the optimization of cycle duration and energy consumption.

Easy access to washing detergents

Hinged door for easy access to storage of chemical tanks – up to three 10 liters.

7" user-friendly HMI

Industrial PLC with intuitive 7″ touch-screen HMI, allowing for 65 programming options.

Full traceability

RS 232 port for printer connection, Ethernet connection to general data system to monitor and validate the washing cycles and/or the data storage. Integrated printer and barcode reader available as options.

Hydraulic quality in Steelco LAB1000 washer

Effective mechanical action with complete coverage is crucially important to assure optimal cleaning during the washing process. Customized washing pumps and circuits ensure a high flow rate combined with adequate spray pressure. The washing chamber and spray arms as well as tank filters are made of high quality AISI 316 L stainless steel (DIN 1.4404). The 500 liters washing chamber has rounded edges in order to avoid any dirt traps, minimizing the risk of microbial growth.

Wide range of racks, inserts, trays and accessories

A comprehensive choice of racks and accessories to meet different capacity and cleaning demands allows maximizing the numbers of different utensils and glassware that can be washed, preventing movement and damage, and ensuring complete coverage of the loads.

Washing efficacy

High-quality stainless steel AISI 316 washing chamber and washing arms for optimal performance, with washing and drying injection system integrated into the same circuit. Low friction bearings ease chamber and cart washing arms rotation for improved efficiency in water and air distribution. Triple water filtering system captures residue preventing re-circulation and extending the pump life.