Freestanding glassware washer - for medium and large size laboratories, 640 SL

The LAB 640 SL is a large capacity, fully automatic frontal loading laboratory glassware washer aimed to satisfy medium/large size facility needs. This washer is equipped with a motorized vertical sliding down door thus allowing the reduction of the space needed in the laboratory.

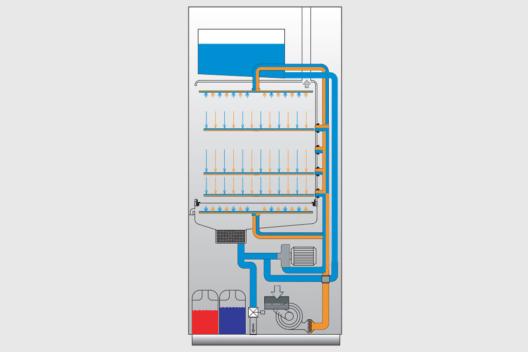

Electrical or steam heated, this unit is capable of injection washing and drying on up to 3 levels on 4 possible rack locations, providing maximum flexibility through multiple chamber configurations, depending on the height of the loaded items. All the levels are equipped with telescopic bearing rails that enable easy and safe loading and unloading of the glassware. The upper levels can be removed depending on the height of the loaded glassware.

The Steelco LAB 640 SL is equipped with a full visibility glass door and a easy access drawer on-board chemical storage. The optional filtered forced air drying system with adjustable time and temperature settings help to ensure the complete inside and outside drying of all the glassware. The availability of an optional pre heated tank allows to perform a final non recirculated rinse.

Key features of glassware washers 640 series from Steelco

Flexible solutions of LAB640L washer

Washing and drying (option available) system on up to three levels with four possible rack locations providing maximum flexibility.

Washing process quality

Flow meter for accurate volumetric dosing of chemicals and a conductivity sensor for measuring of the conductivity value during the final rinse phase are available upon request.

Water quality for laboratory washing

Triple water filtering system captures residue preventing re-circulation and extending the pump life.

Drying efficacy

Built-In HEPA 14 filtered forced air drying system ensuring the complete internal and external drying of all the glassware. It allows for adjustable time and temperature settings, optimizing cycle duration and energy consumption.

5.7" user-friendly HMI

Intuitive control system with industrial PLC, 5,7” touch screen display, allowing for 40 programming options.

Traceability

Process recording and complete cycles data information can be stored on a memory stick connected to the integrated USB interface or can be printed by the optional built-in printer.

Washing efficacy

Effective mechanical action with complete coverage is crucially important to assure optimal cleaning during the washing process. Customized washing pumps and circuits ensure a high flow rate combined with adequate spray pressure. The washing chamber and spray arms as well as tank filters are made of high quality AISI 316 L stainless steel (DIN 1.4404). The 350 l washing chamber has rounded edges in order to avoid any dirt traps, minimizing the risk of microbial growth.

Wide range of racks, inserts, trays and accessories

A comprehensive choice of racks and accessories to meet different capacity and cleaning demands, allowing to maximize the numbers of different utensils and glassware that can be washed, preventing movement and damage, and ensuring complete coverage of the loads.

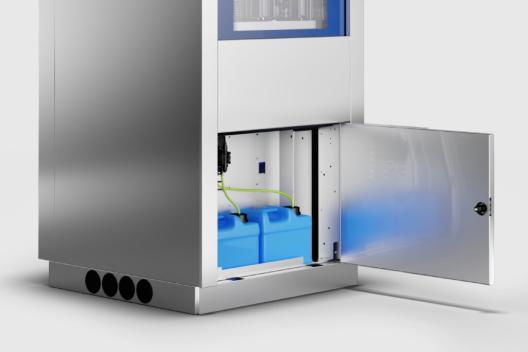

Easy access to chemicals

Steelco laboratory glassware washer features a convenient hinged door allowing for easy access to storage of chemical tanks of up to two 10 l, guaranteeing easy maintenance.

Single pass final rinse option

A pre-heating tank configured with electrical heating elements allows for a no-recirculate final rinse. Water temperature of the pre heating tank can be varied to best suit the customer's procedures. A built-in air compressor provides compressed air to operate the pneumatic valve system of the hydraulic circuit for not re-circulated final rinse.