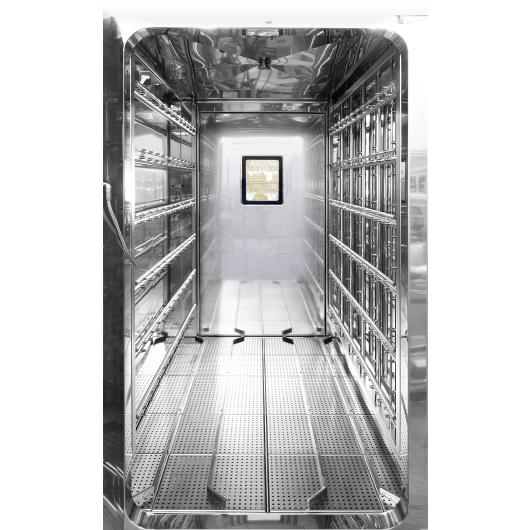

The AC 8500 series cage and rack washer is a heavy duty, large capacity, hydro-spray, steam or electric heated washer specifically designed to support the throughput of medium and large size facilities. The compact size and frontal access for servicing allow it to be installed in premises of reduced dimensions.

The AC 8500 is standard equipped with two side heated water tanks (one for the wash solution and one for the rinse water) and two dosage units, results in greater flexibility in cycle development. The rinse circuit is separate from the wash circuit. Multiple oscillating spray arms guarantee a complete and continuous coverage of the load and the chamber providing excellent wash results in a short cycle time.

The AC 8500 cage and rack washer features sliding doors, operator multi-language touch screen HMI with auto diagnostic checking that constantly monitors and displays status.

The AC 8500 airtight chamber allows the machine to be used as a decontamination chamber for:

- Hydrogen Peroxide

- Chlorine Dioxide

- Chemical fogging

- Thermal disinfection with clean steam

Overall size: may vary depending on choosen options

Chamber depth: 2300mm

Door passage WxH: 1170x2150 mm

Pit depth in the floor: 100 mm or 150 mm according to machine configuration

Note: Customized chamber is available upon request. Washer can be designed to any size to meet new or existing applications.

- Single automatic sliding door (stainless steel with window or full glass)

- Optional second door with interlock function available - for SPF pass‐through application

- Chamber made of 316L stainless steel

- Chamber light

- Double safety cable inside the chamber

- Chamber static floor screens with adjustable-removable runners

- Full wash and rinse separated circuits

- One side tank for the recirculation of the wash solution

- One side tank to pre-heat the final rinse water, equipped with a dedicated rinse pump

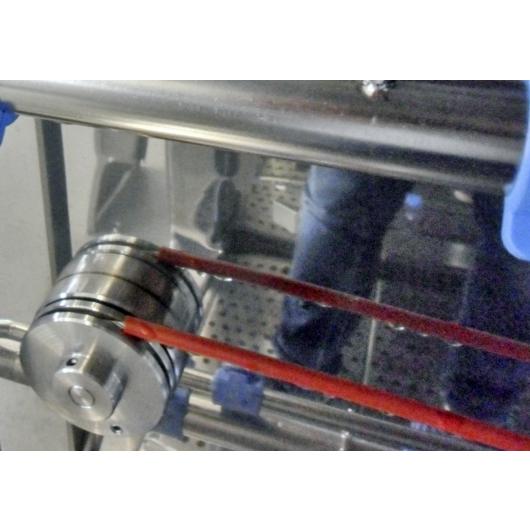

- Pneumatically driven oscillating spraying arms

- Steam or electric

- Tool‐free in‐line self‐cleaning filter

- Two dosage units (on board)

- Industrial PLC with Touch Screen HMI and USB port

- Tele-service ready

- Self-start feature

- All models include:

- Single automatic sliding door (stainless steel with window or full glass)

- Door 1170 mm x 2150 mm

- Chamber depth 2300 mm

- Chamber made of 316L stainless steel

- Chamber light

- Double safety cable inside the chamber

- Chamber static floor screens with adjustable-removable runners

- Single process hydraulic circuit for recirculated wash and rinse phases

- Pneumatically driven oscillating spraying arms

- Steam or electric

- 5.5KW (7.5HP) wash pump with variable frequency drive

- Tool‐free in‐line self‐cleaning filter

- Dedicated IVC‐Rack wash cycle

- Two dosage units (on board)•

- Air valve with HEPA filter for fast end of the cycle aeration phase

- Exhaust fan with variable frequency drive

- Industrial PLC with Touch Screen HMI and USB port ready

- Tele-service ready

- Tablet Connectivity ready

- Software utilities consumption E-meter

- Self-start feature

- Emergency stop button

- Full wash and rinse separated circuits (AC 8500 only)

- One side tank to pre-heat the final rinse water equipped with a dedicated rinse pump (AC 8500 only)

- Second door with interlock function

- Chamber customization to fit existing pit

- Chamber frame for existing deep pits

- Upgrade for aquatic tank cycle

- Air differential seal

- Tilting floor (for standard chamber)-recommended when drying of flat surfaces is required

- Connection to bottle cart -semi-automatic

- Connection to bottle cart -automatic

- Steam condenser for non-vented application

- Electrical drying system

- Additional dosage unit on board

- Decontamination with Steelco H2O2 onboard generator

- Decontamination with external generator

- On board thermal printer

- Volt free contact

- Cycle phase related multicolor lighting of the chamber

- Internal IP 67 chamber socket

- Steelco Data View -cycle traceability software

- Loading / Unloading ramp

- On board Air Compressor

- Bottle basket wash rack

- Rodent cage universal rack

- Rodent cage universal rack short version

- FAT Steelco Standard protocol and execution

- SAT protocol

- IQ-OQ protocols