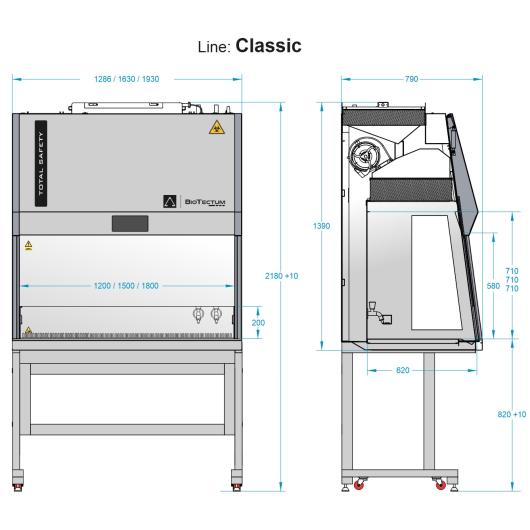

Laminar flow cabinet, Biotectum Classic NEO

Save the space with Classic NEO laminar flow cabinet from Biotectum. With cabinet width ca. 1050 mm, the chamber provides smart solution for laboratories with limited space. Cabinet is equipped with two electronically commutated motors, have a higher working space, and have an interior made of stainless steel and tempered glass, which gives the products exceptional elegance while maintaining all the required safety features for use.

Technologies used in Classic microbiological safety cabinet Biotectum

TEC FLOW: Automatic digital compensation of air velocity in the chamber and at the outlet depending on changing operating conditions.

TEC AUTO CONTROL: System self-diagnostics.

TEC REMOTE CONTROL: Remote diagnostics of chamber settings.

TEC SUSPEND: A mode that keeps the chamber in continuous operation while reducing energy consumption.

TEC DSAM: Setting of evaporation time, fan operation, standstill time, number of repetitions and neutralisation time and ventilation. An H2O2 evaporator is required to carry out the process.

TEC TURN&TOUCH: Classic control panel with membrane keypad and selection knob.

Key features of Biotectum microbiological safety cabinets

Electrically moveable front window

Electrically movable front window, positioned at an angle to the worktop with edge position monitoring and automatic stopping function at the optimum height above the worktop in the working position.

Electric fans

Two or three high-quality electronically commutated V-shaped (Zephyro System ®) fans guarantee ideal laminar distribution as well as low current consumption and low noise emissions. Two temperature-compensated airflow sensors, one for laminar flow and one for protective curtain measurement.

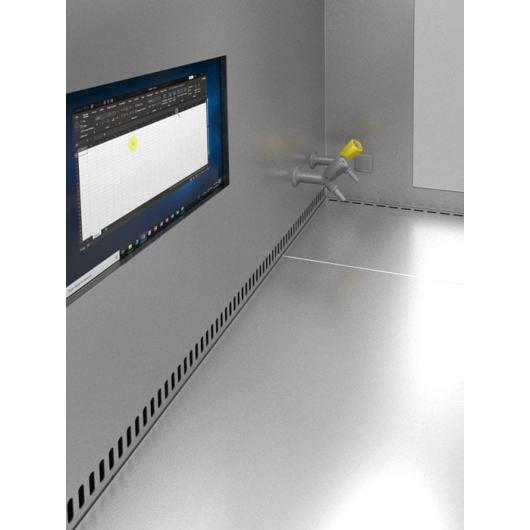

Integrated connections

Flammable gas, inert gas and power supply connections are located at the top of the chamber, so there are no pipes protruding outside the chamber. Biotectum chambers can be moved closer to furniture or walls.

LED information strip

LED light strip, visual information on the operating status of the unit.

Seamless stainless steel AISI 316L

The interior of the work area is made entirely of AISI 316L stainless steel in a seamless design with rounded sides to minimise the number of surfaces posing a risk of contamination.

Colour options

Personalisation of the colour of stylistic elements. RAL 2002 Vermilion standard.

High-quality connections

Internal utility installations with valves from the Italian company TOFF, 230 V sockets manufactured by Berker.

Intuitive control

The CLASSIC panel with its dedicated function keys and membrane keypad provides a robust element for managing the operation of the laminar chamber. The Turn&Touch knob enables precise and intuitive navigation through the menu of available functions. The numerical values of the flows are displayed and easy to read from both a sitting and standing position.

Stainless steel worktop

AISI 316L stainless steel worktop, solid or asymmetrically divided.

Stainless steel bowl

AISI 304 stainless steel bowl with optional electrostatic bacteriostatic coating.

Emergency power supply

Autoprotect System – the connection of the chamber to the UPS emergency power supply and the corresponding software enables further chamber operation and gives the necessary time to protect the test material properly. In a fraction of a second, it cuts off the power supply to electrical sockets and electro-valves while maintaining the correct safe operating conditions of the chamber.

Diagnostic connector

Diagnostic connector for connection of an optional module for remote verification of chamber operating parameters by an authorized service center or manufacturer via GSM or Wi-Fi.

Easy glass cleaning

The construction of the chambers is designed to allow easy cleaning of the front glass enclosing the working area on both sides.

V-shaped air intake

V shaped air inlet on the air curtain which eliminates the requirement for additional armrests.

- Full, removable, non-sectioned worktop, acid-resistant stainless steel AISI 316L

- Frame for the cabinet made of closed profiles, height 800 mm, to the worktop 835 mm + 30 mm for adjustment

- Stylistic elements Vermilion RAL 2002

- BR DESIGN version - interior of the work area made entirely of acid-resistant stainless steel type 1.4404, AISI/ASTM 316L in a seamless construction with rounded sides, worktop and a V-shaped air inlet made of stainless steel type 1.4404

- Permanently fixed UV lamp

- 3 electrical sockets (2 on the left, 1 on the right side of the working chamber)

- USB connector for software update

- Port for HEPA filters DOP test

- MODBUS RTU port for cooperation with BMS (Building Management System)

- RS-485 communication port, which allows several cabinets to be connected to one bus to collect information about their operation and alarms centrally

- TEC TURN@TOUCHTM control panel

- TEC AUTO CONTROLTM system auto-diagnosis

- TEC REMOTE CONTROLSTM remote diagnostics of cabinet settings

- TEC FLOWTM automatic digital airflow speed compensation

- Clock / date

- Display contrast adjustment

- ADDITIONAL VALVES

- ---------

- Valve for flammable gases

- Valve for flammable gases with solenoid valve (switched on from the control panel)

- Valve for technical gases

- Valve for technical gases with solenoid valve (switched on from the control panel)

- -------------------------------------------------

- WORK SPACE EQUIPMENT & CONSTRUCTION

- ---------

- Worktop removable, sectioned

- Temperature sensor in the working chamber

- Additional armrests, set of 2 pcs.

- Adjustment of lighting intensity of working area

- Built-in computer monitor IPS 19” IP 65 LED, the option includes 2 x USB connectors in the working area and connectors on the rear wall of the device for connecting a PC

- Additional 230 V electric socket

- Stainless steel rod mounted on the back wall of the working area for hanging food bags

- Under-counter filter model Advanced Under-counter filter model Standard

- GR DESIGN version - interior of the work area made entirely of acid-resistant stainless steel type 1.4301, AISI/ASTM 304 in a seamless construction with rounded sides, electrostatically painted with antibacterial and chemically resistant paint (protective coating IGP-DURA®). Worktop made of acid-resistant stainless steel type 1.4404, AISI/ ASTM 316L with IGP-DURA® coating, optionally without IGP-DURA® coating

- MR DESIGN version - interior of the working area made entirely of acid-resistant, polished (mirror effect) stainless steel type 1.4301, AISI/ASTM 304 in a seamless construction with rounded sides, worktop and a V-shaped air inlet made of acid-resistant polished (mirror effect) stainless steel type AISI/ASTM 316L

- -------------------------------------------------

- CABINET FRAME

- ------

- Module for connecting the cabinet to exhaust ventilation

- Version with increased load capacity up to 50 kg

- Frame on wheels for the cabinet made of closed profiles, height 800 mm, to the worktop 835 mm, wheels blocked with leveling feet

- Frame for the cabinet made of closed profiles, height 700 mm to the worktop 735 mm

- Frame on wheels for the cabinet made of closed profiles, height 750 mm, to the worktop 785 mm, wheels blocked with leveling feet

- Electrically adjustable frame for the cabinet E-STAND 200, it is possible to set the height of the worktop in the range of 635 - 835 mm

- Electrically adjustable frame for the cabinet E-STAND 400, it is possible to set the height of the worktop in the range of 750 - 1150 mm

- Culverts in the side windows

- Sewage connector (eg. drainage of the fluids from the filtration set)

- Stylistic elements in a different color

- -------------------------------------------------

- SAFETY&PROCEDURES

- ---------

- Control of external exhaust fan

- Mode „AUTOPROTECT” - UPS emergency power supply to continue working with the cabinet after a power failure

- Preparation and execution of DQ, IQ, OQ, PQ procedures